Hidden in the recesses of our buildings, behind walls and ceilings, lie cold water storage tanks—unseen yet indispensable. These tanks silently hold the lifeblood of our daily routines, ensuring that clean, potable water flows through our taps and showers. But what happens when these reservoirs become breeding grounds for contaminants?

How do we maintain their purity and safeguard our health? In this comprehensive guide, we’ll dive into the depths of cold water tank cleaning and maintenance.

The Hidden Dangers of Neglect

When left unmaintained, these tanks can become breeding grounds for contaminants. Sediments, algae, and bacteria like legionella can accumulate, posing significant health risks. That’s why it’s really important to keep a close eye on these tanks and clean them regularly.

Why is Cold Water Tank Cleaning Necessary?

1. Contaminants Lurking in the Shadows:

- Over time, dirt, dust, debris, and even harmful bacteria like legionella can accumulate in cold water tanks.

- Neglecting regular cleaning allows these contaminants to thrive, compromising water quality and safety.

Because of the health risks, there’s a legal responsibility for those managing these water systems. This includes getting a Legionella Risk Assessment to identify potential hazards, setting up a Legionella Risk Management Programme to control and reduce risks, implementing and managing precautions to prevent the growth of Legionella, and keeping records of all these activities. These steps are crucial to ensure safety and compliance with health regulations. Learn more on legionella here.

2. The Risks We Face:

- Bacteria and Pathogens: Stagnant water provides a fertile breeding ground for bacteria and viruses. Legionella, notorious for causing legionnaires’ Disease, finds solace in rust, algae, and sludge within these tanks.

- Biofilms: These slimy layers form due to UV radiation, limited nutrients, and other factors. Biofilms harbor pathogens and contaminate the water.

- Sediment: Metals dissolve over time, settling as sediment at the tank’s bottom. While not directly harmful, sediment can affect taste and odor.

3. Legal Compliance and Health Assurance:

- Regular cleaning aligns with guidelines such as HSG274 and ACoP L8.

- It ensures that your water remains clean, safe, and compliant.

ACoP L8: The “Approved Code of Practice and Guidance on Regulations L8” (ACoP L8) is a document published by the Health and Safety Executive (HSE) in the UK. It provides practical advice on how to comply with the law in terms of controlling Legionella in water systems. ACoP L8 is designed to help duty holders, including employers, those in control of premises, and those with health and safety responsibilities for others, to comply with their legal duties in this area.

HSG274: This is a series of technical guidance documents that are part of the HSE’s Legionnaires’ disease series. HSG274 provides specific guidance on the control of Legionella in different types of water systems. It’s divided into three parts: Part 1 deals with evaporative cooling systems, Part 2 covers hot and cold water systems, and Part 3 addresses other risk systems.

Together, ACoP L8 and HSG274 offer comprehensive guidance on assessing the risk of Legionella, implementing control measures, and maintaining water systems to prevent the proliferation of the bacteria. They emphasise the importance of regular monitoring, cleaning, and maintenance of water systems, as well as keeping records of all safety-related activities. Following these guidelines is crucial for ensuring the health and safety of individuals who might be exposed to water systems in various settings, such as workplaces, public buildings, and residential properties.

The Art and Science of Tank Cleanin

Cleaning these cold water storage tanks is a critical and detailed process. It’s not just about removing visible dirt; it involves draining the tank, meticulously removing sediments, disinfecting the interior, and ensuring no harmful residue is left behind. This process safeguards the water quality and, by extension, our health.

More Details on Tank Cleaning:

- Initial Inspection and Preparation: The first step is a thorough inspection of the tank. This helps identify any existing issues like cracks, leaks, or signs of corrosion. Before starting the cleaning process, it’s important to ensure that the tank is isolated from the water system to prevent contamination during cleaning.

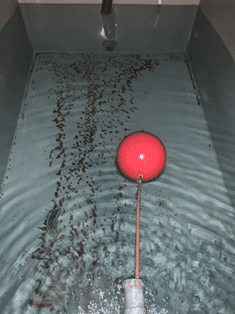

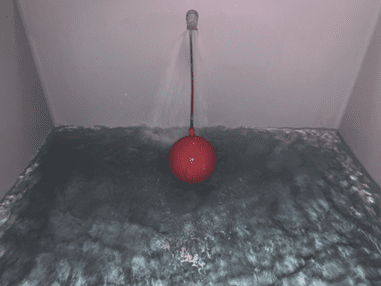

- Draining the Tank: The next step is to completely drain the tank. This allows for a thorough examination of the interior surfaces and helps in identifying any sediment buildup, biofilm, or signs of corrosion that might not be visible when the tank is full.

- Sediment Removal: Over time, sediments can accumulate at the bottom of the tank. This sediment can include minerals, dirt, and other particulates that have settled over time. Removing these sediments is crucial as they can harbor bacteria and other microorganisms. This is usually done by manually scooping out the sediment or using specialised vacuums.

- Disinfecting the Interior: After sediment removal, the next critical step is disinfection. This involves using specific chemical agents or treatments designed to kill bacteria and other harmful microorganisms. The choice of disinfectant depends on several factors, including the tank material and the type of contamination. Care must be taken to ensure that the disinfectant is applied to all interior surfaces.

- Rinsing and Flushing: Post-disinfection, it’s essential to thoroughly rinse and flush the tank to remove any residues of the cleaning and disinfecting agents. This is important to ensure that the water stored in the tank post-cleaning is safe for use.

- Final Inspection and Testing: After the cleaning and disinfecting process, a final inspection is conducted. This might include testing the water for microbiological contaminants to ensure that the cleaning process has been effective.

- Documentation and Record Keeping: Keeping detailed records of the cleaning process, including the methods used, chemicals applied, and results of any post-cleaning testing, is essential. This documentation is important for regulatory compliance and future maintenance planning.

This comprehensive cleaning process ensures that the cold water storage tanks remain a reliable source of clean water. It’s a critical component of maintaining water quality and, consequently, protecting public health. Regularly undertaking this process is key to preventing the growth and spread of harmful bacteria like Legionella and ensuring the longevity of the water storage infrastructure.

Consistent Maintenance for Long-term Purity

Regular inspections and cleaning are key to maintaining tank purity. These preventive measures help identify potential issues like leaks or early signs of contamination. Additionally, routine cleaning, whether annual or biannual, is essential in preventing the buildup of harmful substances.

More Details on Long-Term Purity

Consistent maintenance is vital for ensuring the long-term purity of water in cold storage tanks. Let’s dive into why regular inspections and cleaning are crucial:

- Regular Inspections: These are essential to detect any potential problems before they escalate. During an inspection, professionals look for signs of wear and tear, corrosion, leaks, or any damage that could compromise the tank’s integrity. Inspections also involve checking for any early indicators of biological contamination, such as algae growth or biofilm development, which can lead to more serious issues if left unchecked.

- Preventing Contamination: Regular maintenance helps in preventing the buildup of harmful substances like sediments, bacteria (including Legionella), and algae. If these contaminants accumulate, they can not only affect the taste and smell of the water but also pose significant health risks.

- Cleaning Frequency: The frequency of cleaning depends on various factors, including the size of the tank, its usage, the water quality in the area, and environmental conditions. In general, it’s recommended to clean water tanks at least once a year, but in some cases, more frequent cleaning, like biannually, might be necessary.

- Routine Cleaning Process: This involves emptying the tank, thoroughly scrubbing and removing any sediment or deposits, and then disinfecting it. After cleaning, the tank should be rinsed and flushed properly to ensure no cleaning agents are left behind.

- Leak Prevention: Regular maintenance also includes checking and repairing any leaks. Leaks not only waste water but can also introduce contaminants into the tank, compromising the water quality.

- Record Keeping: Maintaining a log of all inspections, cleanings, and repairs is essential for tracking the tank’s condition over time. This record helps in planning future maintenance and can be crucial for regulatory compliance.

- Professional Expertise: While some aspects of maintenance can be handled in-house, it’s often beneficial to engage professionals, especially for more comprehensive inspections and cleaning. Professionals have the necessary equipment and expertise to carry out the task effectively and safely.

In summary, consistent maintenance of cold water storage tanks is key to ensuring water quality and safety. Regular inspections and cleaning not only help in maintaining the purity of the water but also extend the lifespan of the tank, ensuring a reliable supply of clean water for the long term.

Seeking Professional Expertise

There are instances where the complexity of tank maintenance necessitates professional expertise. Water quality specialists have the tools and knowledge to ensure tanks not only remain clean but also adhere to health and safety standards.

More reason to seek professional expertise:

- Complex Maintenance Needs: While some basic maintenance tasks can be managed in-house, many aspects of water tank maintenance can be complex and require specialised knowledge. This is particularly true for larger tanks, tanks in critical facilities, or tanks that have shown signs of significant contamination or damage.

- Expert Assessment: Water quality specialists are trained to assess and address a variety of issues that might not be immediately apparent to the untrained eye. They can conduct thorough inspections, identify potential risks, and provide recommendations for corrective actions.

- Advanced Tools and Equipment: Professionals have access to advanced tools and equipment that are essential for effective cleaning, inspection, and repair of water storage tanks. This includes high-pressure cleaners, underwater cameras for internal inspections, and specific tools for repairing or replacing tank components.

- Compliance with Regulations: Water quality and safety are subject to various health and safety regulations. Professionals are up-to-date with these regulations and can ensure that your tank maintenance complies with the latest standards. This is crucial to avoid legal issues and to ensure the safety of those using the water.

- Effective Disinfection Techniques: Properly disinfecting a water tank is a critical part of maintenance, and it requires specific knowledge about the types of disinfectants to use and their proper application. Professionals can ensure that the disinfection process is thorough and effective, without leaving harmful residues.

- Handling Complex Contaminations: In cases of severe contamination, such as a Legionella outbreak, professional expertise is essential. These situations require a targeted and strategic approach to eradicate the bacteria and prevent its recurrence.

- Long-Term Maintenance Planning: Beyond immediate repairs and cleaning, water quality specialists can provide valuable insights for long-term maintenance planning. They can suggest improvements, upgrades, and a maintenance schedule tailored to the specific needs of your water storage system.

- Training and Education: Professional services often include educating the client about basic maintenance and monitoring practices. This knowledge transfer can be valuable in maintaining water quality between professional cleanings.

In summary, seeking professional expertise for water tank maintenance is crucial for ensuring the safety, efficiency, and longevity of your water storage system. The specialised skills and tools that professionals bring to the table are invaluable in maintaining the highest standards of water quality and compliance with health and safety regulations.

Concluding Thoughts on Water Tank Importance

These tanks are not just passive containers; they are active, vital elements in ensuring the availability of clean and safe water – a resource fundamental to our daily lives. Our exploration into their maintenance and care highlights the critical role they play in our health and well-being.

In conclusion, the significance of cold water storage tanks in our buildings is paramount. These integral components are essential in ensuring we have access to clean and safe water, a necessity for our health and well-being. Regular maintenance and attention to these systems are not just about fulfilling a duty; they are about upholding a commitment to public health and safety.

Here at Enviro FWA, we understand the critical importance of maintaining these systems. We are equipped to provide comprehensive tank cleaning and maintenance services, ensuring that your water storage systems meet the highest standards of cleanliness and safety. Our team of experts is dedicated to delivering quality service, ensuring the longevity and purity of your water supply. Trust us at Enviro FWA to take care of your water storage needs, keeping your health and safety at the forefront.